Wire cleaners and wire rope lubricators are crucial in the field of cable repair, where precision is key. These tools are crucial for making sure that the cable runs smoothly and has long-lasting life in various industries. In this post, we dive into the importance of wire rope lubricators and cleaners for wires in the maintenance of cables, exploring their functions, benefits, and the transformative impact they have on the overall efficiency of operations.

Understanding Wire Rope Lubricants:

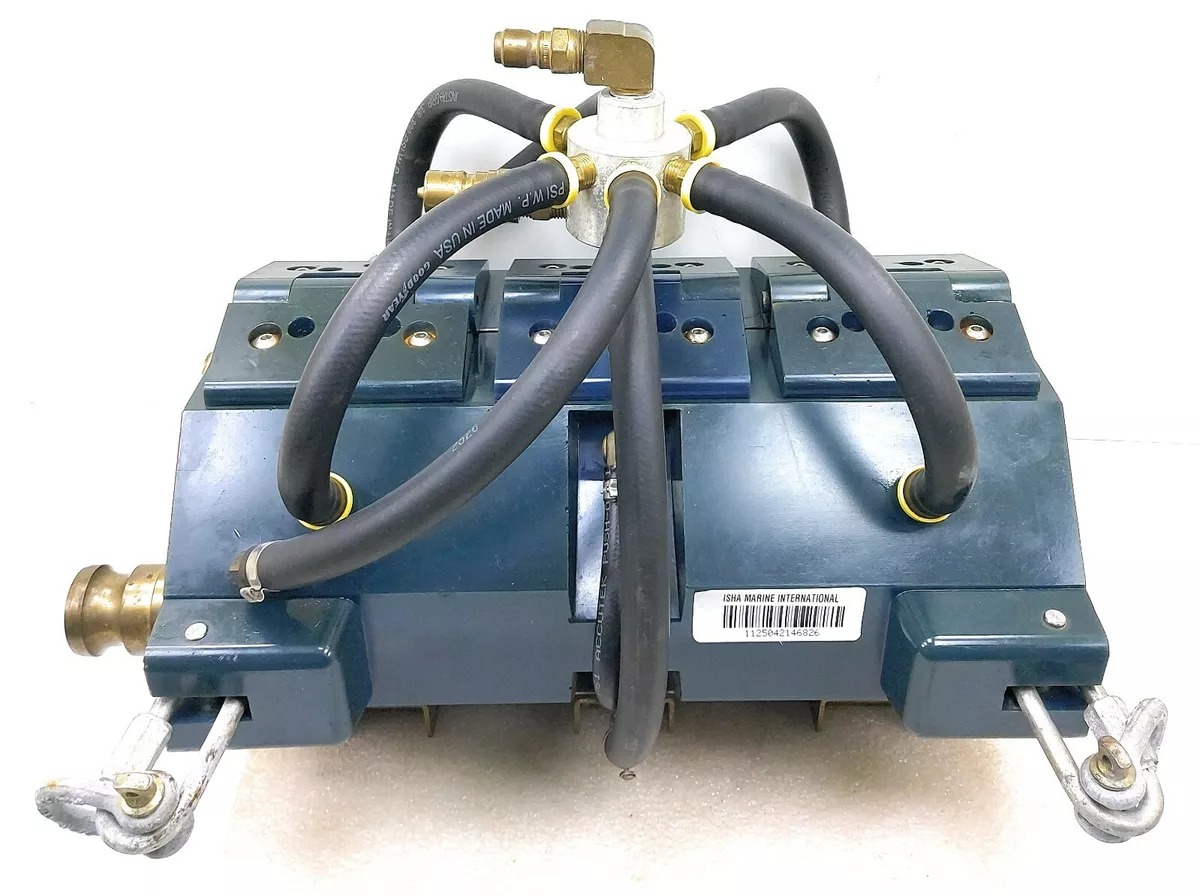

Wire Rope Lubricators are specialized machines that allow you to provide lubrication to wire ropes in a logical method. This process is crucial for stopping corrosion, reducing friction, and enhancing the durability of the cable. The lubricator makes sure that the lubricating agent is evenly distributed across the length of the wire rope. This provides complete protection from wear and tear.

The Role of Wire Cleaners in Cable Maintenance:

Wire cleaners (also referred to as cable cleaners) are also essential to keeping the hygiene and cleanliness of cables. They are designed to remove contaminants, debris and fluids that might build up over the cable during various processes. When working in harsh conditions using wire cleaning products is necessary to ensure optimal performance.

Optimizing Cable Lifespan:

Combining wire cleaners with the lubrication of wire rope can prolong the life of cables. With the use of wire rope cleaners to remove contaminants and applying lubrication, cables are protected from damaging influences like corrosion, friction, or external elements. This protects the integrity the cable and leads into increased efficiency and reduced maintenance expenses.

The efficiency of the application

Wire Rope Lubricators are made to be easy to use and efficient in use. They can be employed on different types and sizes of wire ropes, allowing for flexibility in cable maintenance practices. Lubrication that is automated is applied in a methodical manner, ensuring consistency and eliminating the possibility of uneven coverage. See more at Wire Cleaning

The ability to adapt in challenging environments:

In fields where cables are exposed to harsh environments, like those used in construction, drilling and maritime operations the flexibility of wire rope lubricators or wire cleaners is essential. They are made to withstand harsh conditions and offer the most reliable tools for maintaining cables with various settings.

Maintenance solutions that are affordable:

An approach that is proactive to cable care using cables and lubricants, as well as cleaners are a better cost-effective choice in the long-term. The initial investment for these sophisticated tools is in comparison to the costs associated with cable replacements along with downtime and costly repairs resulting from neglecting proper maintenance practices.

Conclusion:

In conclusion Wire rope lubricators as well as wire cleaners stand as guardians of integrity of cables, making sure that they are durable, precise and maximum performance across many industries. Cleansing away contaminants as well as the application of lubricant contributes to the long-term preservation and durability of cables. This reduces maintenance and improves operational efficiency. As businesses continue to rely on cables for critical operations, the use of modern tools for maintenance of cables like wire rope lubricators, wire cleaners becomes more than a choice but a strategic requirement for long-term success and reliability.

Unleashing Efficiency: The Ultimate Guide To Wireline Cleaning With Air, Water, Or Steam

Wire cleaners and wire rope lubricators are crucial in the field of cable repair, where precision is key. These tools are crucial for making sure that the cable runs smoothly and has long-lasting life in various industries. In this post, we dive into the importance of wire rope lubricators and cleaners for wires in the maintenance of cables, exploring their functions, benefits, and the transformative impact they have on the overall efficiency of operations.

Understanding Wire Rope Lubricants:

Wire Rope Lubricators are specialized machines that allow you to provide lubrication to wire ropes in a logical method. This process is crucial for stopping corrosion, reducing friction, and enhancing the durability of the cable. The lubricator makes sure that the lubricating agent is evenly distributed across the length of the wire rope. This provides complete protection from wear and tear.

The Role of Wire Cleaners in Cable Maintenance:

Wire cleaners (also referred to as cable cleaners) are also essential to keeping the hygiene and cleanliness of cables. They are designed to remove contaminants, debris and fluids that might build up over the cable during various processes. When working in harsh conditions using wire cleaning products is necessary to ensure optimal performance.

Optimizing Cable Lifespan:

Combining wire cleaners with the lubrication of wire rope can prolong the life of cables. With the use of wire rope cleaners to remove contaminants and applying lubrication, cables are protected from damaging influences like corrosion, friction, or external elements. This protects the integrity the cable and leads into increased efficiency and reduced maintenance expenses.

The efficiency of the application

Wire Rope Lubricators are made to be easy to use and efficient in use. They can be employed on different types and sizes of wire ropes, allowing for flexibility in cable maintenance practices. Lubrication that is automated is applied in a methodical manner, ensuring consistency and eliminating the possibility of uneven coverage. See more at Wire Cleaning

The ability to adapt in challenging environments:

In fields where cables are exposed to harsh environments, like those used in construction, drilling and maritime operations the flexibility of wire rope lubricators or wire cleaners is essential. They are made to withstand harsh conditions and offer the most reliable tools for maintaining cables with various settings.

Maintenance solutions that are affordable:

An approach that is proactive to cable care using cables and lubricants, as well as cleaners are a better cost-effective choice in the long-term. The initial investment for these sophisticated tools is in comparison to the costs associated with cable replacements along with downtime and costly repairs resulting from neglecting proper maintenance practices.

Conclusion:

In conclusion Wire rope lubricators as well as wire cleaners stand as guardians of integrity of cables, making sure that they are durable, precise and maximum performance across many industries. Cleansing away contaminants as well as the application of lubricant contributes to the long-term preservation and durability of cables. This reduces maintenance and improves operational efficiency. As businesses continue to rely on cables for critical operations, the use of modern tools for maintenance of cables like wire rope lubricators, wire cleaners becomes more than a choice but a strategic requirement for long-term success and reliability.